Researchers get ‘compact’ hard X-ray machine to work

On a Friday afternoon in September, Jom Luiten, Professor of Coherence and Quantum Technology, receives a phone call from the lab saying, “Jom, you have to come to the lab now!”. The phone call came from his PhD students Ids van Elk and Coen Sweers, who were still working in Qubit’s basement. Colleague Peter Mutsaers had the misfortune of being on holiday.

Upon arrival at the lab, it quickly became clear what the reason was: the compact X-ray machine, which can make close-knit and adjustable hard X-rays, works! This is reason enough for great joy and a quick message on Monday to all members of the Smart*Light 2.0 research consortium.

Ids van Elk (left) and Jom Luiten ponder the lineup. Photo: Bart van Overbeeke

The reason for this great joy? For that, we have to go back to the start of the research. The journey began, not entirely characteristic of our university, with a painting.

Seeing the layers of a painting

Art historian and materials scientist Joris Dik is affiliated with the Delft University of Technology and is well known for discovering overpainted preliminary studies by Van Gogh, Rembrandt, and Magritte.

With his work, world-famous paintings have been recovered, and he became known for the X-ray analysis of Van Gogh’s painting ‘Grassland’, under which a possible study of the ‘Potato Eaters’ has been recovered.

With his desire to be able to look into paintings with X-rays, he came into contact with Yom Luiten through the Royal Netherlands Academy of Arts and Sciences (KNAW). X-rays make it possible to look beneath the surface of paintings or other art-historical or archaeological objects.

This new X-ray source promises that you can study the chemistry and structure of paint layers at a much higher resolution. This offers, for example, the opportunity to make individual, hidden layers of paint in a painting visible.

Because it is a compact X-ray source, it can, in principle, also be used in a museum. This provides an enormous opportunity for research into museum heritage.

Aerial view of the European Synchrotron Radiation Facility in Grenoble, french city. Photo: iStock / Gregory_DUBUS

A pocket-sized synchrotron?

To look into the layers of paintings, you need a different X-ray source. That’s what Dik was looking for! However, equipment that can generate such precisely destemmed X-rays is not yet available anywhere in a hospital or museum.

In fact, at the moment, this is only possible with a synchrotron. And as the name suggests, those large round synchrotrons (such as the ESRF in Grenoble) have enormous dimensions. Moreover, they are expensive to build and, therefore, always fully booked for research. It is not suitable for scanning a new purchase in a museum and certainly not the entire collection.

While talking to Dik, Luiten came up with a number of good ideas for building a smaller device that can also generate tunable, close-band hard X-rays at a reasonably high intensity. And then with a setup the size of an optical lab table instead of a vast building.

A device of such dimensions will fit in an average-sized lab space and, in principle, even in a shipping container. So a building doesn’t have to be rebuilt to get it in. The device can even hang from the ceiling to monitor production processes with that size.

This linear X-ray source is practically pocket-sized in the world of large synchrotrons. Luiten: “And we even have ideas on making the instrument even more compact.”

Currently, two X-ray sources are widely used: relatively weak sources (so-called X-ray tubes, used in hospitals and dentists) and potent sources (synchrotrons). Now, a mid-range car has been added with the new compact linear source from Jom Luiten and his team. The classic X-ray tube is based on 19th-century technology, over a hundred years old.

X-rays are generated by ‘shaking’ fast electrons back and forth hard. There are several tricks for this: in an X-ray tube, the electrons are abruptly slowed down in a material, while in the synchrotron, the electrons bend extremely hard in a strong magnetic field.

At the source at TU/e, the speeding electrons vibrate in the field with an intense laser pulse. “The physical principle with which the electrons shake back and forth is the same as with a large synchrotron, whether at a kilometer or micrometer scale,” Luiten explains.

Working with a compact linear source, the team accepts a lower intensity than generated by a circular synchrotron. For example, the particles in this linear source race at 99.995 percent of the speed of light, and in the large versions (such as ESRF), they race at 99.9999995 percent of the speed of light. And it is precisely the very compact particle accelerator that makes this X-ray source so unique.

Luiten: “This mid-range capability also makes this source suitable for looking into paintings, silicon wafers, or biological material without damaging it. In addition, this source is special because the energy of the X-rays can be very accurately adjusted to the material you want to detect. You can ‘tune‘ it to visualize any periodic table element. In addition, the light beam is reasonably coherent. Because of this, the measurements you can make with it are of great accuracy.”

In addition to the research of the Smart*Light 2.0 consortium, work is being done on a compact ‘mid-range’ X-ray source in about five other places around the world. But none of them has a particle accelerator as compact as this one, whose energy can be varied quickly and easily.

Radiation for art and archaeology

The first steps were taken when Dik and Luiten met for the first time at the SR2A conference (Synchrotron Radiation for Art and Archaeology) in 2016. “I’m a huge optimist,” Luiten laughs. “I have to be to get these kinds of research projects off the ground and get investors interested.”

The heart of the compact X-ray source: the copper linear particle accelerator. Photo: Bart van Overbeeke

“Thanks to funding from Interreg Flanders-Netherlands and government contributions, it was a great moment when we started our research project in 2018 to build a compact machine to make these hard X-rays.”

“At first, I thought we could do that in three years. Unfortunately, we ran late and dealt with delays due to the COVID pandemic. The furnishing of the lab in the building in which we are now located, Qubit, was also considerably delayed. That affected our schedules.”

A working prototype

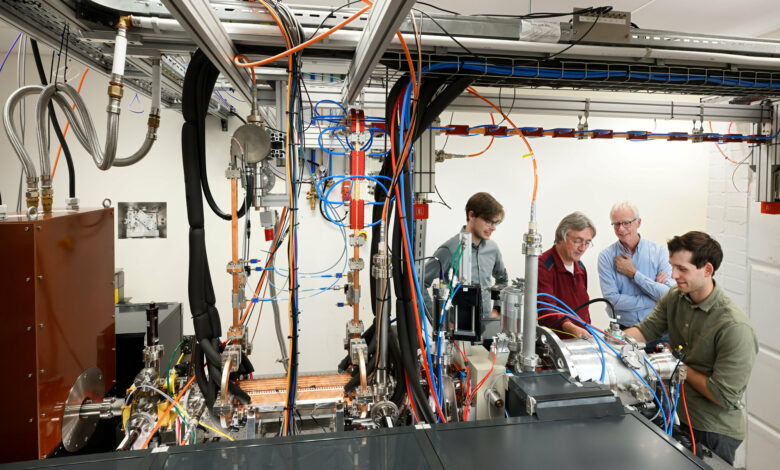

It is the first working prototype in their lab in the basement of Qubit. Or, as Luiten poetically calls it, their ‘compact particle accelerator’. It is one and a half by three meters in size, and to be safe, lead bulkheads and concrete walls have been placed to allow the researchers to do their work safely.

This is a standard measure in particle accelerator labs against undesirable harmful forms of radiation. Thanks to an intelligent design, such extensive radiation shielding will no longer be necessary in the final implementation.

In their lab, the researchers built the compact prototype synchrotron, which has now succeeded in generating hard X-rays for the first time. “After all those years of research, we knew we were close,” Luiten explains. “So it was getting more and more exciting. Nevertheless, Peter (Mutsaers, ed.) went on holiday, and I went home that Friday after some office work.”

We really enjoyed that evening in the lab. We had a working hard X-ray source. Now for real!

Professor Jom Luiten

Peter Mutsaers and Coen Sweers in the control room of the lab setup of the compact X-ray source. Photo: Bart van Overbeeke

The euphoria about this milestone is no less. “Ids, Coen, and I really enjoyed that evening in the lab. The week before, Coen and Ids had taken measurements with Peter to suppress annoying background noise. Exactly what was needed. We had a working hard X-ray source. Now, for real!”

And the best thing about the device is that it can generate different wavelengths very easily, as hoped. “We simply use a rotary knob to vary the wavelength and precisely match it to the material or object we want to study,” Luiten explains.

“That is probably what surprises us the most. This device does exactly what we predicted with our models and theory. For a physicist, that makes him a bit boring, to be frank. The puzzle is solved.”

The research team at work in the lab at Qubit. Photo: Bart van Overbeeke

Next steps

No matter how beautiful the working prototype is, it is not yet the device that Dik dreamed of, and for which other interested parties from the medical world and industry have now also come forward.

Hessel Castricum, research partner and research fellow in Material Science and Engineering at TU Delft, says: “As far as the application is concerned, it is only now that things are starting. In the coming months, we will be working with the other partners in the consortium to target the radiation to the materials to be studied precisely, to capture it with advanced detection equipment, and then to analyze the data collected in this way. TU Delft and the universities of Antwerp and Ghent are good at this.”

Luiten: “After all, the radiation we generate isn’t only suitable for looking inside paintings. You can also check silicon wafers to see if all the layers and lines are in the right place. Or, as partner Erasmus MC wants, you can use it to research atherosclerosis (hardening of the arteries, ed.) or examine lung tissue with early-stage COVID damage. Due to the high quality of the X-rays, compared to current X-ray scanners, you can get a sharper image of smaller parts in a cell or tissues.”

Castricum adds: “There is still much work to be done in the coming period. In addition to the fact that we – together with the research partners from their Interreg project Smart*Light 2.0 – can carry out measurements on materials, we need to get the most out of the source, for example, by further increasing the intensity and focusing the laser and electron beam even better.

“The next step is to make a real proof of concept. So that we can look inside a painting with this source. Our work is certainly not done yet,” Luiten concludes with visible pleasure.

On to the next exciting chapter.

Latest news

Keep following us